Welcome to GALVATEC

Since 2006, GALVATEC has developed its capacities in Surface Treatments and Non destructive Testing, focusing exclusively on the exigent Aeronautic sector.

Due to a correct management of the growth of the company, GALVATEC has been increasing its technologies and facilities, and after the first 6 years of existence, it has reached the following figures:

- Two productions sites with over 5.500 m2 prodcution area.

- Over 120 qualified professionals.

- Process certifications issued by the main Prime contractors (Airbus, Boeing y Embraer)

Due to a correct management of the growth of the company, GALVATEC has been increasing its technologies and facilities, and after the first 6 years of existence, it has reached the following figures:

- Two productions sites with over 5.500 m2 prodcution area.

- Over 120 qualified professionals.

- Process certifications issued by the main Prime contractors (Airbus, Boeing y Embraer)

Full Management Service

GALVATEC offers to their clients a Full Management service, based on the following:

- Continuous search for Excellence in all our technologies

- Internal organization focused on our three main technologies: Machining, Surface Treatments and Assembly

- Manufacture Engineering, Quality Engineering and Program Management

- Supply Chain Management

GALVATEC's future is to continue growing, developing capacities, and offering turn-key solutions to our clients, from our position as a TIER-2.

- Continuous search for Excellence in all our technologies

- Internal organization focused on our three main technologies: Machining, Surface Treatments and Assembly

- Manufacture Engineering, Quality Engineering and Program Management

- Supply Chain Management

GALVATEC's future is to continue growing, developing capacities, and offering turn-key solutions to our clients, from our position as a TIER-2.

BIENVENIDOS A GALVATEC

Since 2006, GALVATEC has developed its capabilities in Surface Treatments and Non-Destructive Testing focusing exclusively on the demanding aeronautical sector.

Due to a correct management of the growth of the company, GALVATEC has been increasing its technologies and facilities in a sustainable way, having several production centers with over 120 qualified professionals and Process Certifications issued by the main Prime contractors (Airbus, Boeing and Embraer).

GALVATEC offers to their clients a Full Management service, based on the continuous search for Excellence, an Internal Organization focused on the main technologies, Manufacture Engineering, Quality Engineering and Program Management and a supply chain management.

GALVATEC's future is to continue to growing, developing capacities, and offering turn-key solutions to our clients, from our position as a TIER-2.

Due to a correct management of the growth of the company, GALVATEC has been increasing its technologies and facilities in a sustainable way, having several production centers with over 120 qualified professionals and Process Certifications issued by the main Prime contractors (Airbus, Boeing and Embraer).

GALVATEC offers to their clients a Full Management service, based on the continuous search for Excellence, an Internal Organization focused on the main technologies, Manufacture Engineering, Quality Engineering and Program Management and a supply chain management.

GALVATEC's future is to continue to growing, developing capacities, and offering turn-key solutions to our clients, from our position as a TIER-2.

OUR TECHNOLOGIES

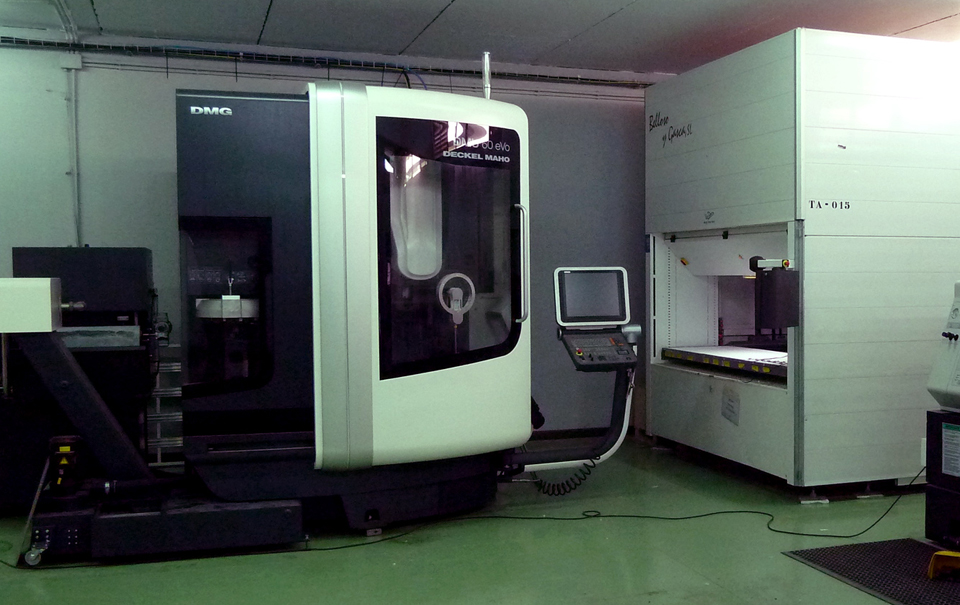

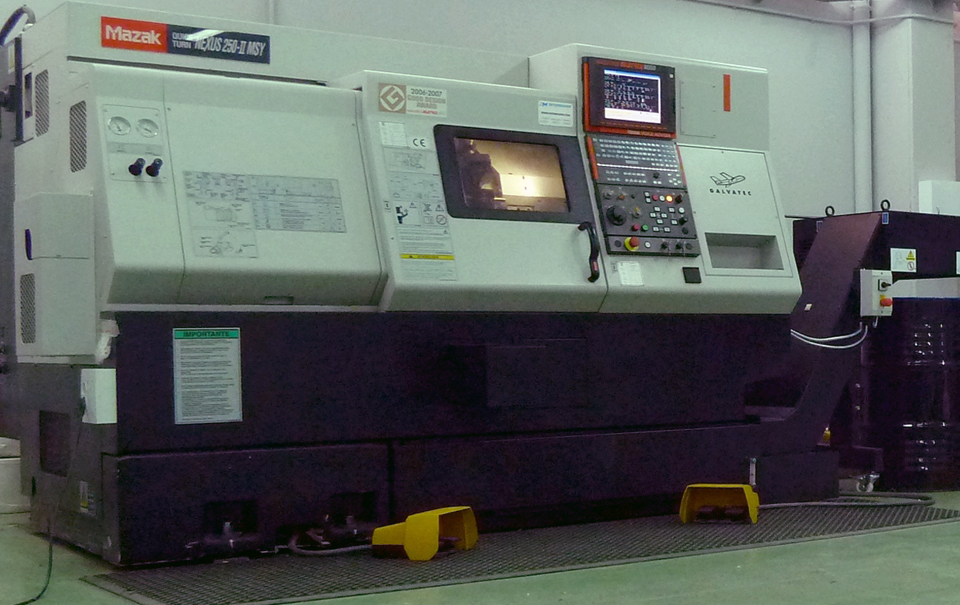

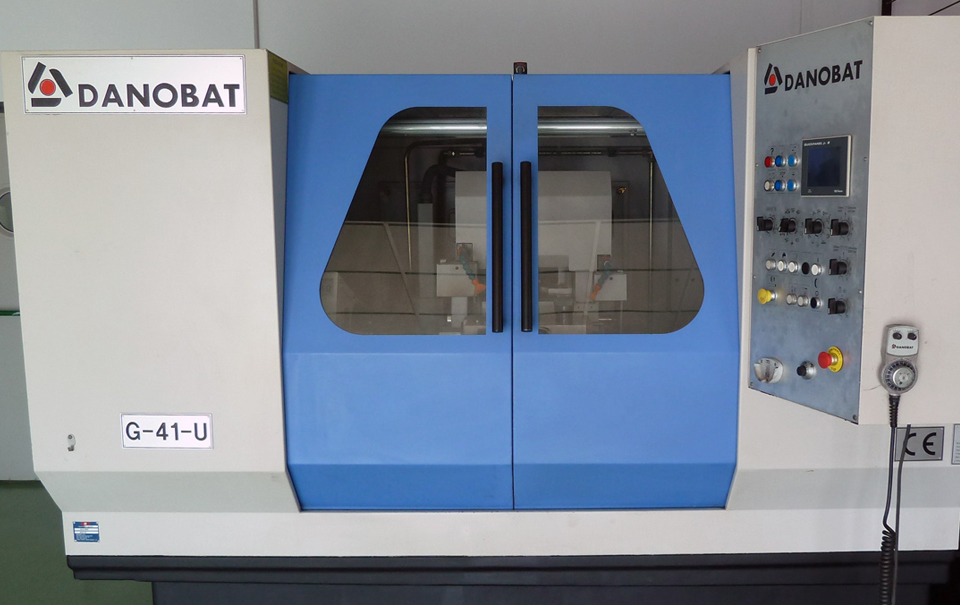

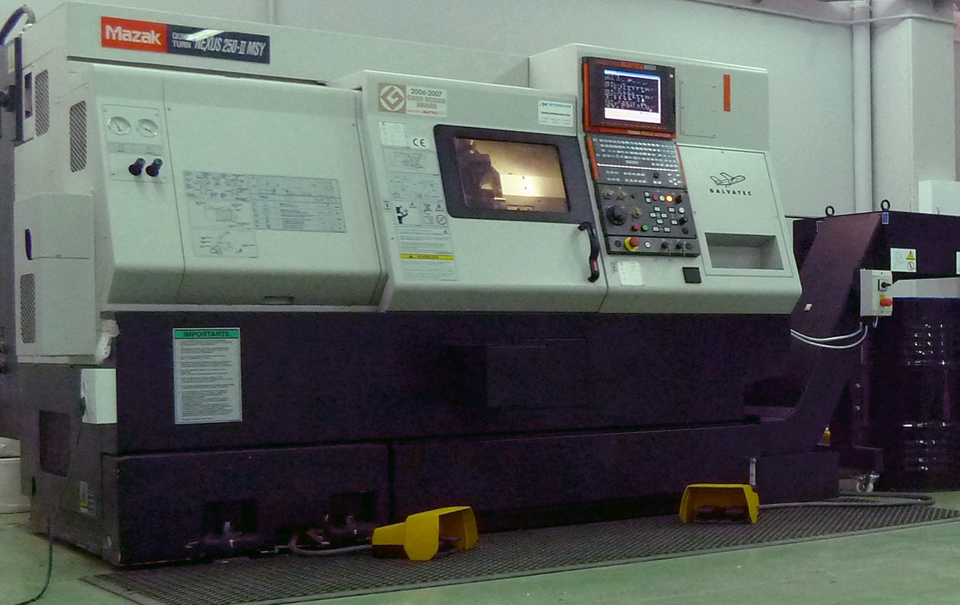

Machining and Turning

Titanium 5 axis CNC machining

Aluminium 5 axis CNC machining

3 axis Turning

3 axis CNC milling

Precision Boring

Grinding

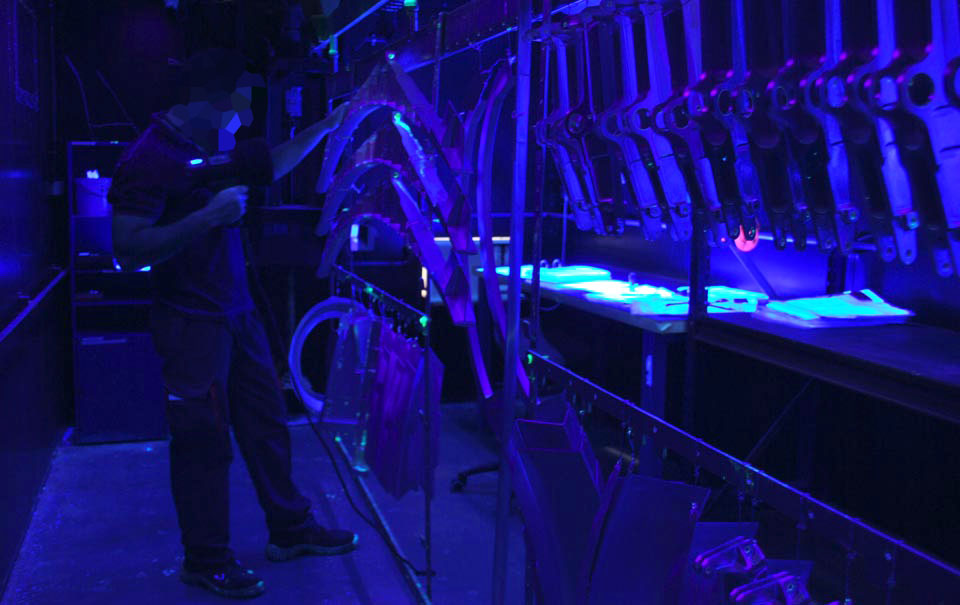

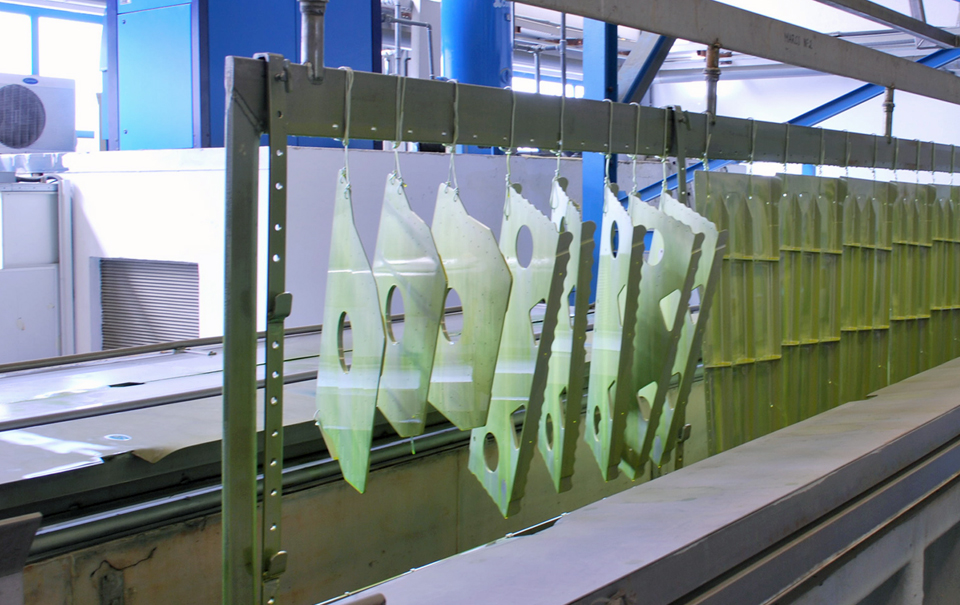

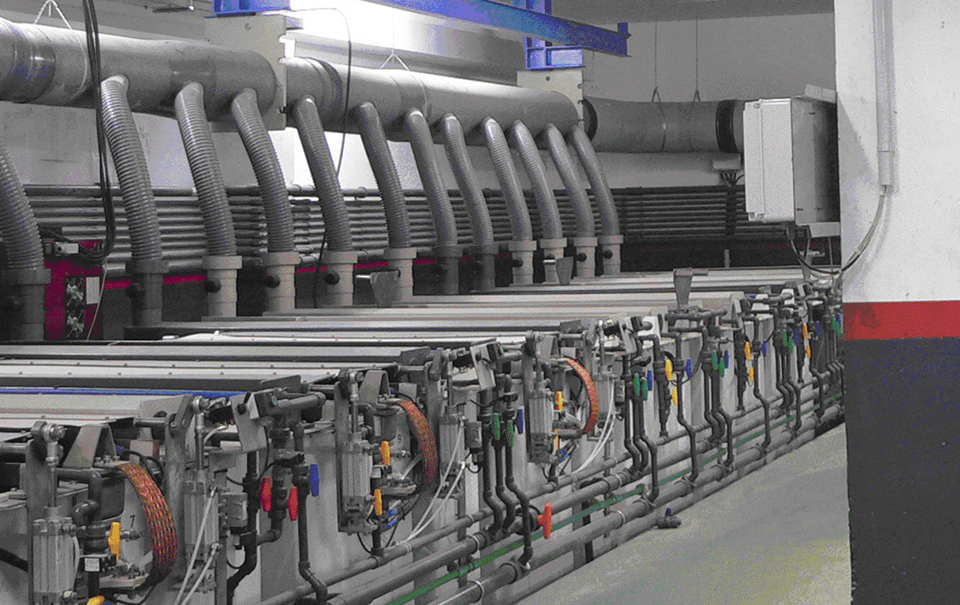

Surface Treatments

Electrolytic Cadmium Plating

Hard Chromium Plating

CRES Passivation

Phosphatising type M

Zinc-Nickel coating

Chemical Conversion Coating (Alodine 1200)

Al and Ti Sulphuric Acid Anodising

Tartaric Sulphuric Acid Anodising

Boric Sulphuric Acid Anodising

Primer and Topcoat application

Pre-penetrant etching of Ti and Al

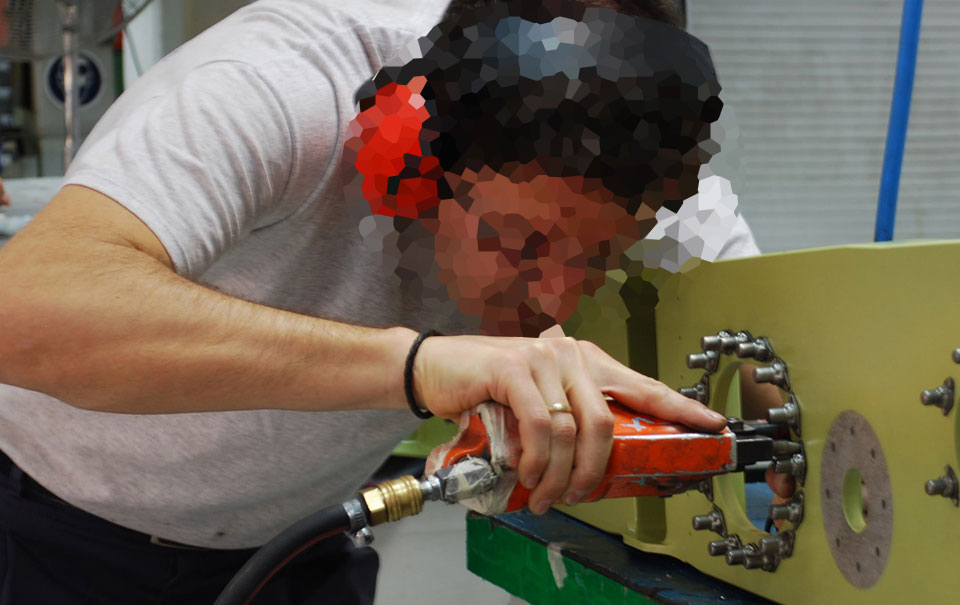

Metallic Sub-Assemblies

Rivetting

Bushing installation

Bearing installation

Non-Structural Bonding

Sealant Application

Panting of sub-assemblies

Heat Treatments

Deembrittlement

Stress Relieve

Non-Destructive Testing

Hardness and Conductivity Check

Liquid Penetrant Crack Detection

Magnetic Particle Crack Detection

Shot Peening

Glass bead shot peening

Steel Shot Peening

Dry Blasting

Assembly, Painting and Edge Sealing of Composite Structures

Assembly on Composite Parts

Edge Sealing

Final Painting of Aerostructures

Chemical Analysis and Testing Lab

volumetric Assessmet

Dry and Wet Adhesion test

Impact Adhesion test

Salt Spray Corrosion test

Atomic absorption

X-Ray Spectrophotometry

Coating Thickness Measurement

Final Inspection

Tridimensional Measurement DEA

Dimensional Inspection

Marked with ink

PDF catalogue

Manufacturing of Aeronautic Parts and Sub-Assemblies

Main Programs

Contact

GALVATEC S.L.

Phone: (+34) 954 115 026 - 954 115 027

Email: galvatec@galvatec.es

P.E. Areronáutico, Autovía A4, Km 528

C/Juan Olivert, 22

41300 - La Rinconada

Sevilla (Spain)

To contact us, please ask any questions or suggestions filling out the form.

We will contact you as soon as possible.

Financiación Pública y Ayudas